Palm oil press processing machine line plant

HOTLINE

+ 86 13837162063

Product Introduction

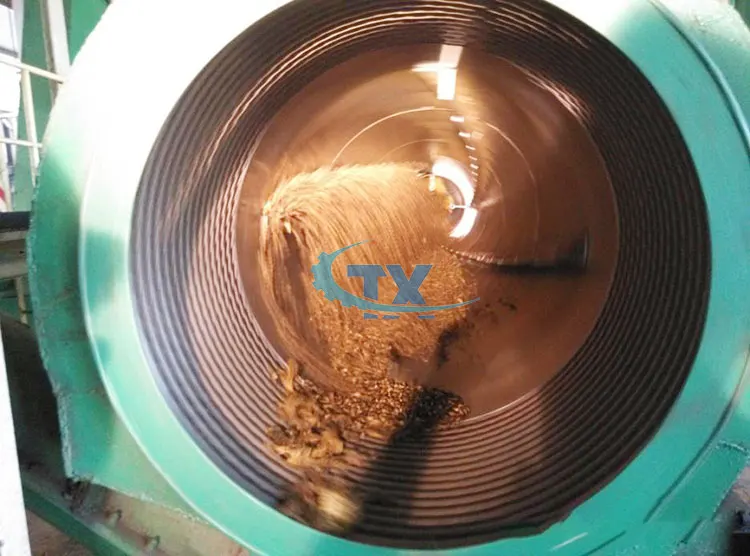

After pressing,we can get palm cake and palm nut. Pam nuts will be conveyed to palm recovery system to get palm kernels, fiber and palm shell. Palm cake will be conveyed to boiler room as fuel. After filtering,centrifuging, and vacuum drying, we can get crude palm oi (CPO), the CPO can be sold directly or used for further processing. The sewage from all the plant will be processed by sewage treatment to reach discharge standard. Sludge can be used for fertilizer in palm plantation. All the process cycle features with short operation cycle, high automaticity, energy conservation and environmental protection.

Palm oil press processing machine line plant

1 Compact and strong structure, and easy operation.

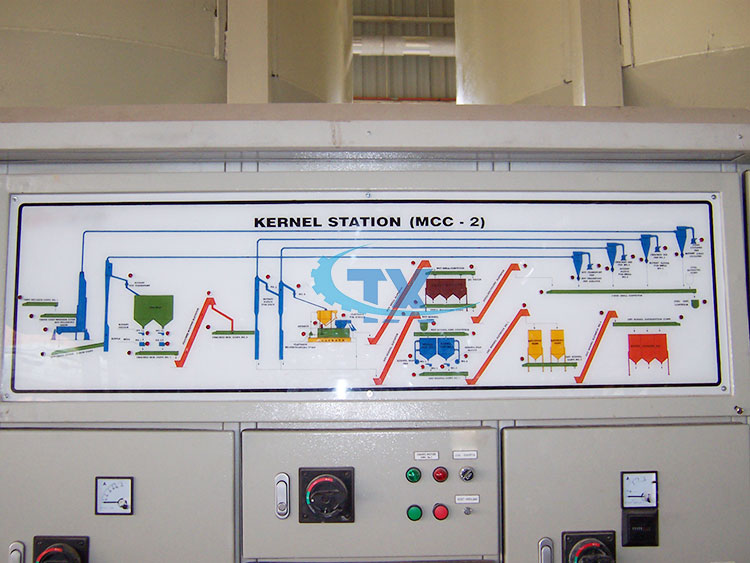

2 The automatic control system which can adjust barrel pressure.

3 High oil pressing efficiency, and residual oil in cake is less than 8%.

4 Low crushing efficiency for palm nut.

5 Invest is small, quick gains.

Product Features